TOM LEADING

THE WORLD

IN PACKING TECH

Do you have any issues

like this?

Even the light work of packaging and hanging strings, it is time-consuming and labor-intensive tasks. By mechanizing such packing work, costs and time are drastically reduced. In this labor-saving era, TOM-YAMADA is contributing to the improvement of work efficiency. Always maintaining a pioneering spirit, we are ready to meet the demands of any user.

For example, in the corrugated industry, the following issues are expected to become increasingly serious in the future.

– Cost reduction

– Productivity improvement

– Labor shortage

– Quality

– Environmental measures

TOM-YAMADA proposes improvement measures to solve these issues.

This is the solution we propose.

We offer solutions to the problems of corrugated board manufacturers and corrugated board users with our TOM Tying Machineusing PE-Tape.

Solution 01

Running costs can be reduced.

Solution 02

High capacity dramatically improves productivity of corrugated-box manufacturing line.

Solution 03

Using PE-tape enables automation for corrugated board users.

Solution 04

Twine Unfolding Device can prevent corrugated board quality from being compromised.

Solution 05

It reduces greenhouse gas emissions and promotes global environmental protection.

FEATURE 01

Cost Reduction

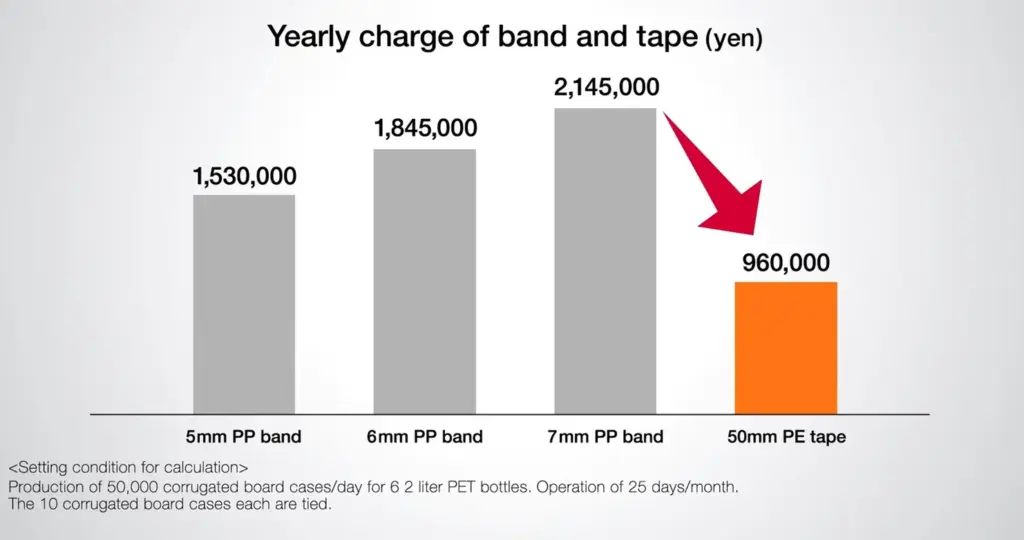

Switching from PP-band packing machines to TOM Tying Machine can significantly reduce running costs.

Up to 55% cost reduction is possible when 7 mm PP-band is replaced with 50 mm wide PE-tape.

In addition, the PP-band Strapping Machine has a complicated welding system that is difficult to repair, although a spare machine may be used in the event of a breakdown,

TOM Tying Machine can be restored simply by replacing the Tying Unit (Main Table Casting), eliminating the need for a spare unit.

The service life of TOM Tying Machines is equal to or longer than that of Box-Making Machines.

In the long term, costs can be equal to PP banding machines, or lower depending on the model.

FEATURE 02

Improving Productivity

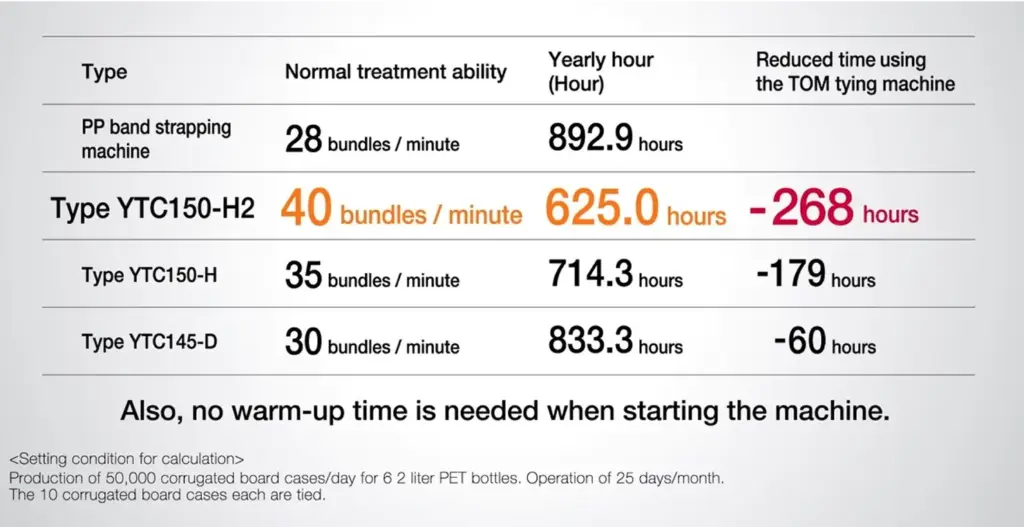

PP-band Strapping Machine require heating, pressurizing, and cooling processes to bond the bands.

Therefore, the time it takes is more than 2 seconds.

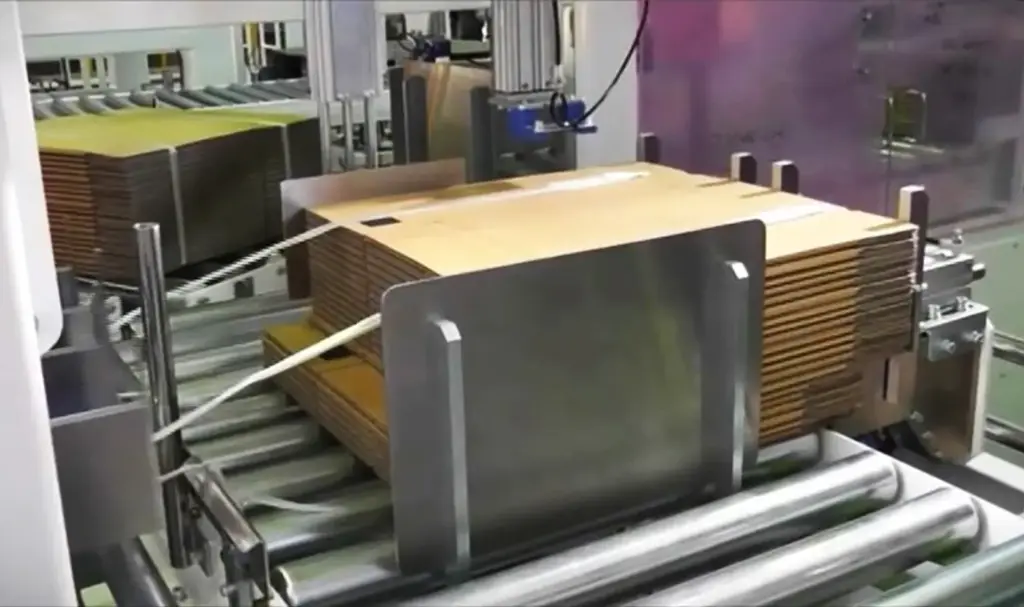

TOM Tying Machine mechanically creates knots in the PE-tape and bundles one bundle in 1.7 seconds.

This improves the productivity of corrugated-box manufacturing line and allows for increased production.

Our high-end model has a regular capacity of 40 bundles/min.,

and is capable of meeting the production speeds of all high-speed Box-making Machines.

FEATURE 03

Contributing to Increased Efficiency and Labor Savings

Japanese beverage and food manufacturers are increasingly automating the feeding of corrugated cases into production lines to solve labor shortages and reduce labor costs.

Automated feeding of corrugated cases into production lines is in progress.

PE string, which is easy to cut, pull out, remove, and store, is ideal for automated feeding.

Compared to PP-bands, PE-tape is lighter and softer.

This property makes it possible for customers who use corrugated cardboard to use automatic feeding.

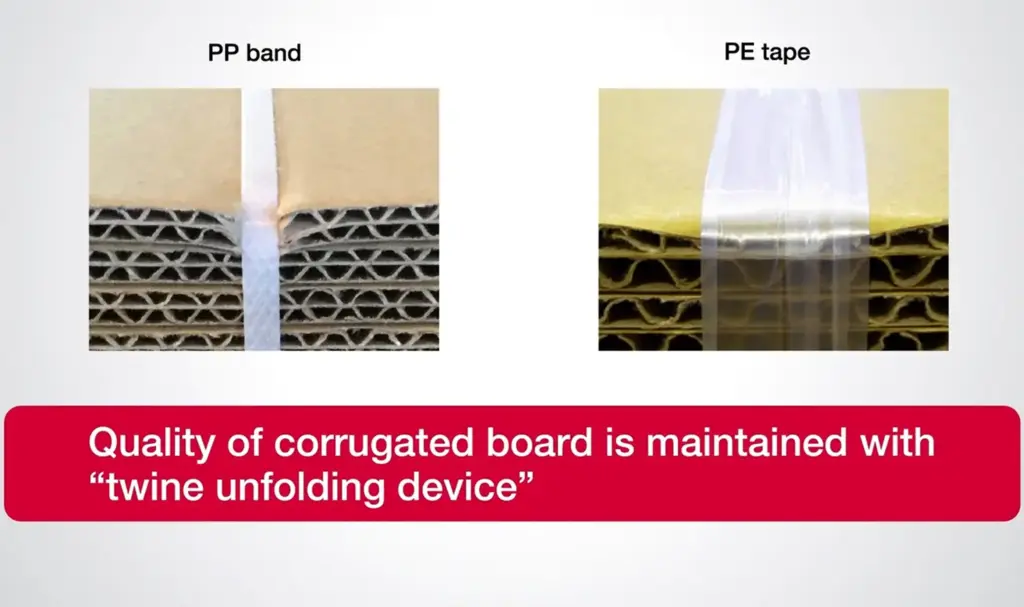

FEATURE 04

Quality Improvement

PP-bands tend to damage corrugated board.

It is difficult to automatically remove PP-bands that have wedged into the core.

In contrast, TOM Tying Machine uses the characteristics of PE-tape to prevent wedging,

The quality of the corrugated cardboard can be maintained and does not interfere with the operation of the automatic feeding system.

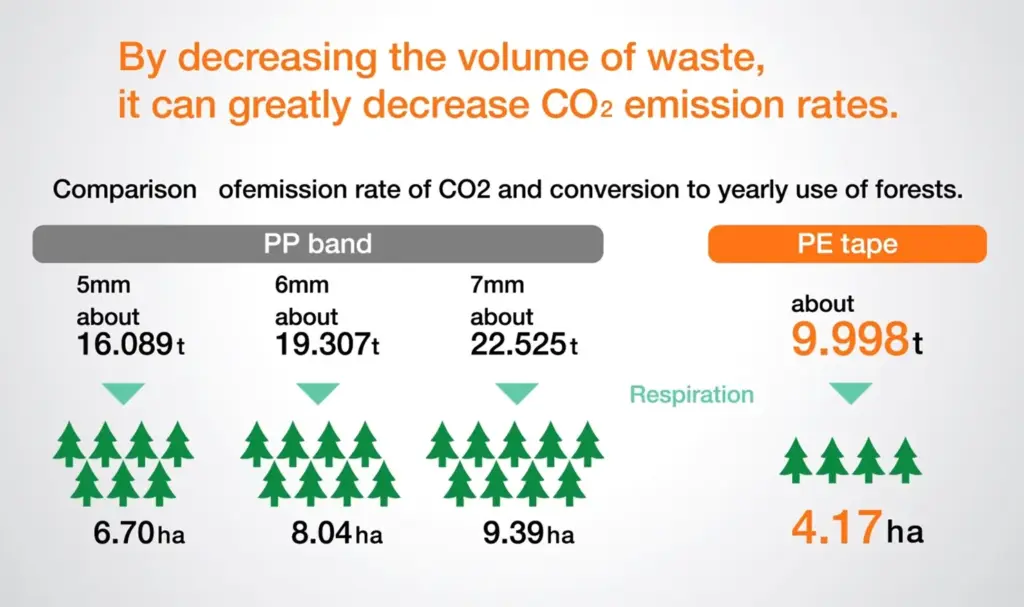

FEATURE 05

Environmental Measures

PE-tape is less bulky and easier to dispose of due to its low rebound. The difference in work speed for disposal is obvious.

By reducing the volume at disposal, CO2 emissions can be greatly reduced.

By switching from PP-bands to PE-tape, we can make a significant contribution to environmental protection.

Have any questions?

PE (Polyethylene) tapes are easy to buy anywhere in the market ? Or users have to buy from supplier (TOM-YAMADA) ?

Several manufacturers produce and sell PE tapes in Japan and East/Southeast Asia. In countries where PE tapes-supplier is located, the supplier sells PE tapes. If not so, customers import PE tapes with containers.

How does the end user (corrugated box user) break the PE tape? By knife or by just pulling as they can with current bundle straps?

Particularly, in Japan there are cutters for tape-cutting in circulation. Of course, it is also possible to pull and untie one side of the knot.

Is there any residue on the PE tapes that could hamper with Food Safety Regulations?

There is not. Don’t worry.