Introduction Flow

INTRODUCTION FLOW

01

Inquiry

Please feel free to contact us.

We will listen to your requirements and operating environment to prepare the best machine and option proposals.

02

Selecting model and option

Based on your needs and the specifications of the case erector, we will select the most suitable machine and necessary options.

03

Quotation

We will present a quotation based on the selected machine and options.

04

Purchase order

Once you are satisfied with the quotation and place your order, it will be officially accepted.

05

Confirming specification

We will confirm the detailed specifications with you and finalize the machine configuration.

06

Mechanical and electrical design

Based on the finalized specifications, we will carry out the mechanical and electrical design.

07

Manufacture

We will manufacture and assemble the machine according to the design.

08

Delivery inspection

We will conduct operational and quality inspections on the completed machine.

09

Installation

We will install the machine at your site and provide necessary construction work, operation instructions, and training.

10

Test run

After installation is complete, we will perform test runs to verify the operation and make adjustments as needed.

11

Acceptance

Finally, you will confirm the machine, and if there are no issues, the delivery will be completed.

SUPPORT 01

Sample provision

We can provide sample of actual bundling with the material you send us. Please contact us for more details.

SUPPORT 02

Installation Support

If you prefer to handle the installation yourself, we also offer remote installation support.

SUPPORT 03

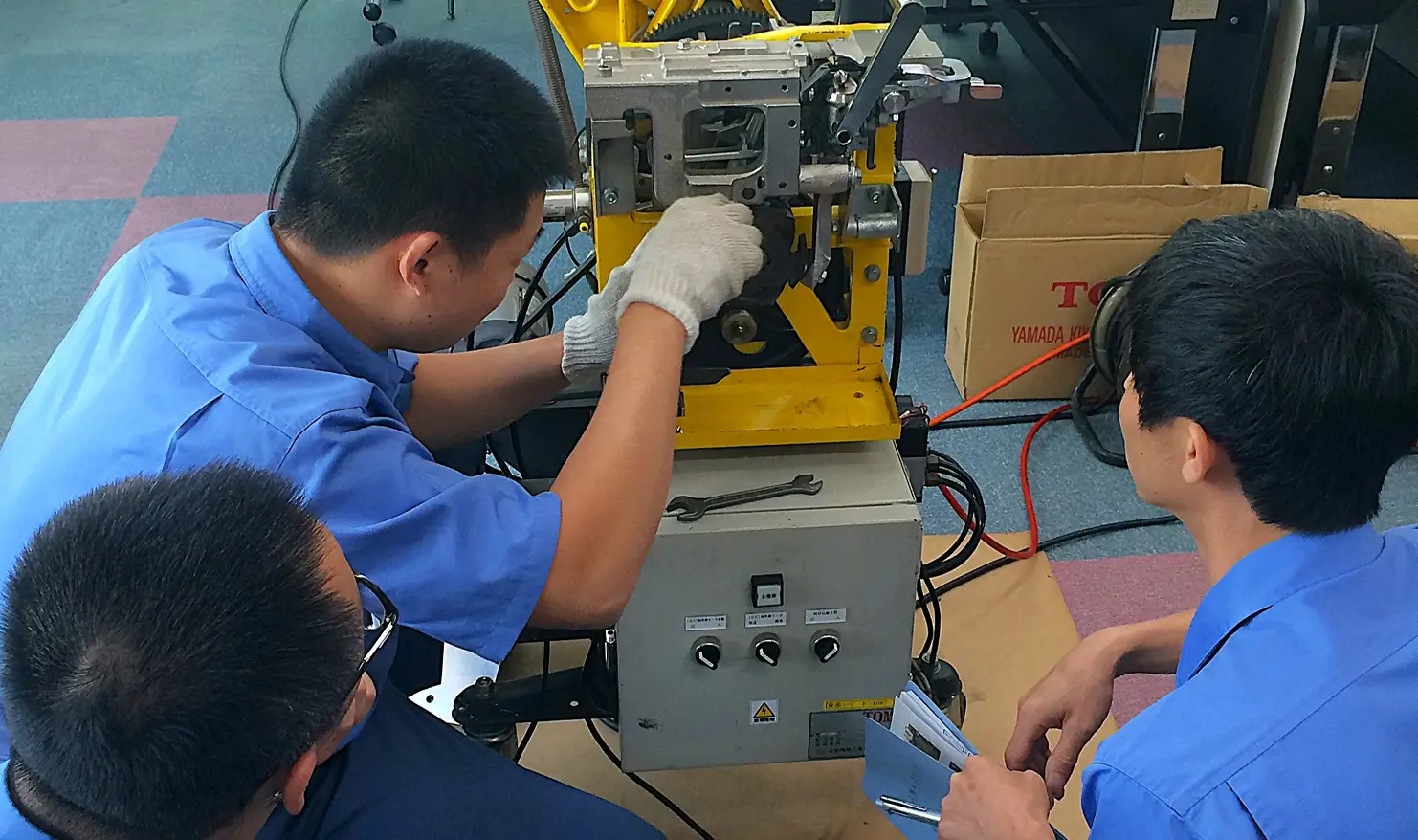

Maintenance Training

We also offer machine maintenance training.

Have any questions?

1. What is the minimum equipment required to operate the machine?

The following two types of equipment are necessary (for standalone operation):

- Electric Power supply

- Air compressor

2. What is the required Information for Selecting the machine’s model?

Please provide the following information when selecting the appropriate machine model:

- Manufacturer name and processing capacity (number of corrugated sheets per minute) of the pre-process (Flexo Folder Gluer etc.)

- Size of the corrugated sheets

- Number of corrugated sheets per bundle

3. What is the required Information for Confirming the machine’s specification?

The required information may vary depending on the machine type.

However, the following information is generally needed:

- Power specifications (Voltage, Frequency)

- Conveyor’s Height

- Paint color (Color Codes are required for the selection. Note: In case of YTC145-SE, you cannot select the color.)

Please confirm this information as soon as possible.

Additionally, the following information could be required:

Communication specification document for pre-process (Flexo Folder Gluer etc.) *Required if data link is available

PE tape specifications (P28/P50)

Language for the control panel and nameplates (English, Chinese, Korean, Vietnamese and Japanese are available)

4. What is the Minimum Requirement for the Machine’s Installation?

The following items are required for the machine installation:

- 2-ton forklift (including an operator)

- Hammer drill (drill bit is not required)

- Work assistants (2 people each for the first and second day of installation)